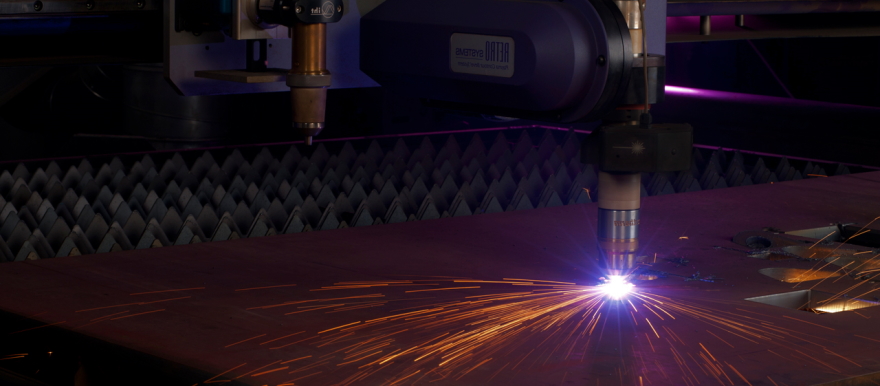

A plasma cutter chops metal by passing air or inert gas via a plasma torch, causing an electrical arc to form, and then pushing plasma through the nozzle tip to cut metal. A plasma cutter’s arc can reach temperatures approaching 45,000 degrees Fahrenheit, making it one of the quickest methods to cut metal. Plasma cutters feature an on/off switch as well as an amperage adjustment that controls how much power is used for cutting. Plasma is typically a highly safe, fast, and clean method to cut metal, as long as the plasma cutter has adequate power to cut via the metal workpiece.

Tips To Choose a Plasma Cutter

The following article will go over some of the most important things to consider if you are about to select a plasma cutting machine using the following plasma cutter selection guide:

Examine The Output Power

Examine The Output Power

A plasma cutter’s power output level (or amperage) determines the layer thickness that can be cut with it. A plasma cutter would often be rated based on its amperage, and you will be able to determine the optimum range of width that it’ll be able to cut. Ensure that this thickness range corresponds to the material you want to cut the majority of the time. A general rule of thumb to remember is that the denser your material, the more amperage you’ll need to cut it.

- High Cutting Quality

Cut quality is among the most important things to consider when purchasing a plasma cutter. Quality cutting has a significant effect on the final product’s quality while also influencing subsequent manufacturing stages. You want a piece that is well-cut and has smooth, clean edges. This ensures that you don’t waste time re-creating the identical item in the later phases of production: the clean and smooth cutting results in a smaller cut width, which results in less wasted material.

- Choosing The Cutting Speed of a Plasma Cutter

Plasma cutters usually have a cutting speed measured in inches per minute (IPM). Your workflow as well as priorities will define what you need but bear in mind that although two plasma cutters might well be able to cut across a 1/2 inch of metal, one may do it in a minute, while the other may take four or five minutes if it has a sluggish cutting speed. Choosing the appropriate cutting speed for your equipment may be the difference between a good investment and a drop in production.